Discover Undercarriage Parts for Heavy Machinery

Comprehending the details of undercarriage components is essential for the ideal efficiency and durability of hefty machinery. From track footwear to idlers, gears, and rollers, each component plays a critical duty in the performance of the devices. Exploring the specifics of these components reveals a globe of accuracy engineering and resilience that keeps hefty equipment operating at its height. Stay tuned as we uncover the value of undercarriage parts and discover the upkeep techniques that can boost the performance of these vital parts.

Significance of Undercarriage Parts

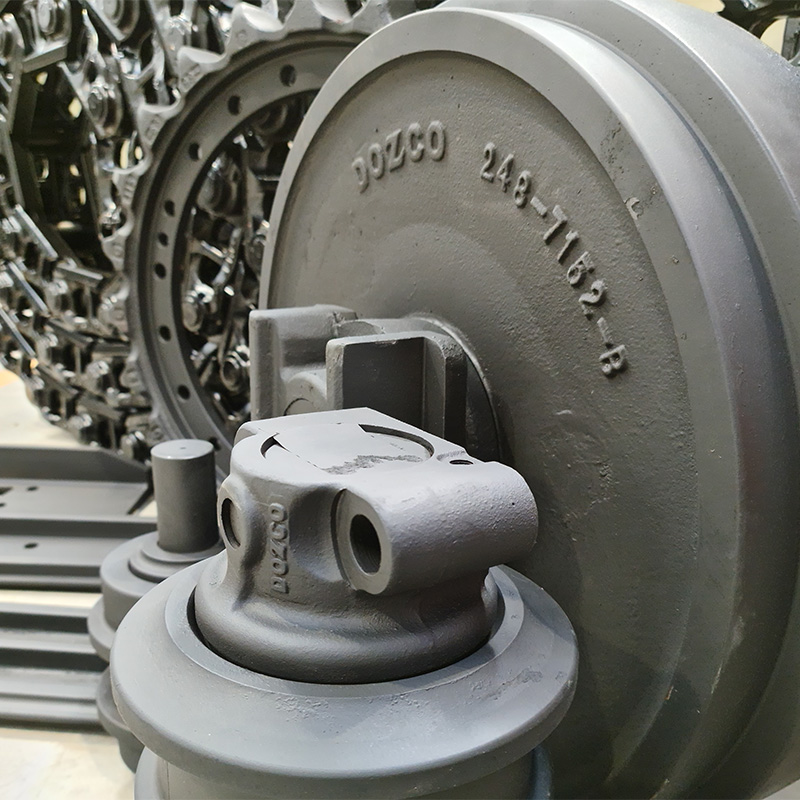

The undercarriage parts of heavy equipment play an essential function in guaranteeing the overall performance and durability of the tools. These elements, consisting of tracks, rollers, idlers, chains, and sprockets, create the structure whereupon the device operates. A well-kept undercarriage not just provides stability and support to the heavy equipment yet additionally adds dramatically to its functional effectiveness and productivity.

One of the crucial benefits of investing in high-quality undercarriage parts is the decrease of downtime and maintenance costs. By making use of long lasting parts that can withstand the roughness of durable applications, operators can reduce the demand for regular repairs and replacements, therefore making best use of the machine's uptime and overall life-span.

Additionally, correctly functioning undercarriage parts ensure ideal weight distribution, grip, and ability to move, allowing the hefty equipment to run efficiently even in challenging surfaces. This reliability is essential for sectors such as agriculture, mining, and building and construction, where tools efficiency directly influences task timelines and success. Finally, the importance of undercarriage components can not be overemphasized in preserving the efficiency and long life of hefty machinery.

Sorts Of Track Shoes

When thinking about the different sorts of track shoes for hefty machinery, it is important to assess their layout and performance in connection with details operational needs. Track shoes are important components of the undercarriage system, giving weight, security, and traction distribution for heavy equipment such as excavators, bulldozers, and spider cranes.

The most usual sorts of track footwear include:

** Grouser Shoes **: Featuring increased metal bars (grousers) along the shoe's surface, these track shoes give improved grip in difficult terrains like mud, snow, and loosened crushed rock. undercarriage parts.

** Double Grouser Shoes **: Similar to grouser footwear however with an extra set of grousers, these track shoes provide even higher grip and security, making them suitable for exceptionally harsh terrains.

** Three-way Grouser Shoes **: With 3 sets of grousers, these track shoes provide optimal traction and security, making them ideal for the most requiring conditions.

Selecting the ideal type of track footwear is crucial for optimizing the efficiency and longevity of heavy equipment while making certain safety and security and effectiveness during procedures.

Feature of Rollers and Idlers

Rollers and idlers play integral roles in supporting and directing the track shoes of heavy equipment throughout operation. Rollers are cylindrical elements that support the weight of the devices and make sure smooth activity along the terrain. have a peek at these guys They aid distribute the equipment's weight uniformly, reducing endure the track shoes and minimizing vibrations. Idlers, on the other hand, overview the more information track chain and aid keep proper stress. By avoiding extreme slack or tightness in the tracks, idlers contribute to the overall security and efficiency of the machinery (undercarriage parts).

Furthermore, idlers and rollers collaborate to keep the track shoes in alignment, avoiding them from slipping or thwarting off during procedure. Properly functioning idlers and rollers are vital for making sure the longevity of the undercarriage system and taking full advantage of the equipment's performance. Regular maintenance and evaluation of these parts are necessary to recognize any kind of indications of wear or damages early, stopping expensive repair work and downtime in the lengthy run.

Duty of Gears in Equipment

Maintenance Tips for Undercarriage Parts

Effective maintenance of undercarriage components is crucial for ensuring the longevity and optimal efficiency of hefty equipment. Regular examination of undercarriage components such as track chains, rollers, idlers, gears, and track footwear is essential to stop pricey go to this website repair services and unanticipated malfunctions. One vital upkeep suggestion is to keep the undercarriage tidy from debris, mud, and other impurities that can accelerate wear and rust. It is likewise crucial to ensure correct track stress to protect against early endure parts. Oiling the undercarriage parts at recommended periods helps to decrease rubbing and expand the life-span of the parts. Monitoring for any type of unusual noises, vibrations, or adjustments in maker efficiency can indicate prospective issues with the undercarriage that require instant interest. By adhering to these maintenance tips diligently, hefty equipment drivers can lessen downtime, lower running expenses, and make best use of the efficiency of their devices.

Final Thought

In conclusion, the undercarriage components of hefty machinery play an important function in making sure the smooth functioning and durability of the devices. Recognizing the significance of track shoes, rollers, gears, and idlers, as well as applying proper maintenance techniques, can greatly influence the total efficiency and effectiveness of the machinery (undercarriage parts). Routine evaluation and prompt substitute of damaged parts are important in taking full advantage of the life-span and productivity of heavy equipment

Rollers and idlers play indispensable roles in supporting and assisting the track shoes of heavy machinery throughout procedure.In hefty equipment, gears offer a vital feature in moving power from the engine to the tracks, enabling the tools to move successfully and successfully. These components are linked to the axles or final drives of the equipment and work in conjunction with the tracks to move the equipment onward or in reverse. Regular examination of undercarriage parts such as track chains, rollers, idlers, sprockets, and track footwear is essential to stop costly repairs and unanticipated malfunctions. Understanding the relevance of track footwear, idlers, rollers, and sprockets, as well as implementing appropriate upkeep practices, can substantially influence the overall efficiency and performance of the machinery.

Comments on “The Ultimate Guide to Extending Lifespan: Undercarriage Parts Maintenance Made Easy”